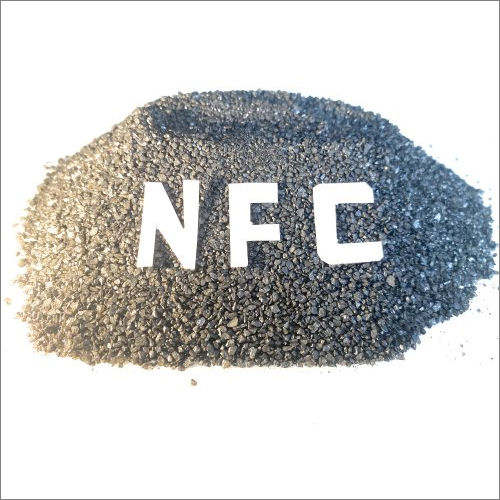

Nozzle Filling Chromite Compound NFC

42 INR/Kilograms

Product Details:

- Application Industrial

- Product Type Mineral Refractories

- Types of Refractories Basic Refractory

- Shape Powder

- Specific Gravity Standard

- Color Black

- Click to View more

X

Nozzle Filling Chromite Compound NFC Price And Quantity

- 42 INR/Kilograms

- 1000 Kilograms

Nozzle Filling Chromite Compound NFC Product Specifications

- Powder

- Industrial

- Mineral Refractories

- Standard

- Basic Refractory

- Black

Product Description

Nozzle Filling Chromite Compound (NFC) is a type of sealing material used to fill gaps and spaces between nozzles and the header plate of a heat exchanger. NFC is made from a mixture of chromite, epoxy resin, and other fillers that provide a high level of heat resistance and durability. The chromite in the compound provides an additional layer of protection against high temperatures and harsh environments, making NFC ideal for use in applications such as oil refineries, chemical plants, and power generation facilities. The compound is typically applied to the nozzle area and allowed to cure, creating a tight seal that prevents leaks and improves the efficiency of the heat exchanger. It is important to follow the manufacturers instructions carefully when applying NFC, as improper application can result in a weak seal or other issues.

Enter Buying Requirement Details